[From mid-2008] My dishwasher’s been making a bad grinding noise that, I think, is the remnant of a broken coffee cup sloshing around in the sprayer assembly. I noticed the screws holding this on are the TORX shape. This got me wondering about the type of screws available and what their trade-offs were.

Enjoy!

The flathead (or “slotted”) screw is an old design, but suffers two shortfalls: it’s hard to center and it’s too easy to apply too much torque, causing the screwdriver blade to pop out and destroy the head. Thus, it’s used primarily in wood products assembled by hand.

The flathead (or “slotted”) screw is an old design, but suffers two shortfalls: it’s hard to center and it’s too easy to apply too much torque, causing the screwdriver blade to pop out and destroy the head. Thus, it’s used primarily in wood products assembled by hand.

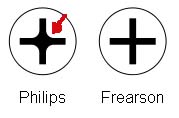

The Phillips, also known as “cross-head” or “plus screwdriver,” was invented by Henry F. Phillips for use on automated production lines. Though he received patents for this (2,046,343, 2,046,837), the design was so widely copied that the patents were lost.

The Phillips, also known as “cross-head” or “plus screwdriver,” was invented by Henry F. Phillips for use on automated production lines. Though he received patents for this (2,046,343, 2,046,837), the design was so widely copied that the patents were lost.

In addition to being self-centering (meaning it won’t go in cockeyed), the slight curvy part at the bottom causes the screw to pop out of the head if too much torque is applied. Though this was a benefit in the 40s, as a homeowner, it’s a pain, especially when doing so bends the metal.

There are several variants of this basic design:

- Japanese Industrial Standard[3] – will not pop out. It’s widely adopted in Asia.

- Frearson – has a more pointed shape of the blade that will not pop out. It’s really hard to see in the image above, but the center does not have the circle where the plus intersects.

- Pozidriv or Supradriv – lack rounded corners, but have four more points of contact. It’s less likely to slip out. The primary disadvantage is people try to use a Phillips screwdriver and have it pop out.[4]

Hex or “Allen” bolts or, among those of us who love verbal intercourse, “sex keys,” are used on bicycles and nearly everything sold at Ikea[5]. It’s simple, it’s cheap, and torque can be constrained by the key’s thickness and width.

Hex or “Allen” bolts or, among those of us who love verbal intercourse, “sex keys,” are used on bicycles and nearly everything sold at Ikea[5]. It’s simple, it’s cheap, and torque can be constrained by the key’s thickness and width.

TORX, or “star,” or “hexalobular internal driving feature,”[2] has a six-point star shaped pattern. Unlike Phillips, that are supposed to pop out if too much torque is applied, TORX heads prevent[2] this popping out, but are prone to being stripped. They’re most often found on cars (where it was rumored their use was to prevent shade tree mechanics from messing with stuff), hard drives and my dishwasher.

TORX, or “star,” or “hexalobular internal driving feature,”[2] has a six-point star shaped pattern. Unlike Phillips, that are supposed to pop out if too much torque is applied, TORX heads prevent[2] this popping out, but are prone to being stripped. They’re most often found on cars (where it was rumored their use was to prevent shade tree mechanics from messing with stuff), hard drives and my dishwasher.

The Robertson screw, invented in 1908, was designed to be easy to use one-handed. Like the Phillips, it’s self-centering and potentially faster to use. When Henry Ford tried them, he found they saved two hours off production time[6]. Robertson wouldn’t license them, so Ford used Phillips.

The Robertson screw, invented in 1908, was designed to be easy to use one-handed. Like the Phillips, it’s self-centering and potentially faster to use. When Henry Ford tried them, he found they saved two hours off production time[6]. Robertson wouldn’t license them, so Ford used Phillips.

![]()

Triple square or “XZN” socket screws are used primarily in Germany on high-torque applications[9].

The other major category is tamper-proof screws, for which there are infinite varieties. Global Fasteners[8] offers custom designs. More common ones include spanner head screws, Torx pin-head, and the one-way slotted (pictured at right).

Sources:

- [1] Images are from Wikipedia, except for the tamper-proof screws, which are from [8].

- [2] ISO 10664, Wikipedia

- [3] Japanese Standard web site.

- [4] Pozidriv screw, Wikipedia

- [5] Ikea. 🙂

- [6] Robertson Screws, Mysteries of Canada

- [7] History of Screws and Screwdrivers, About.com

- [8] Tamper Proof Screws, Global Fasteners

- [9] Triple Square Screws, Wikipedia.